discover

Fluidisation

Systems

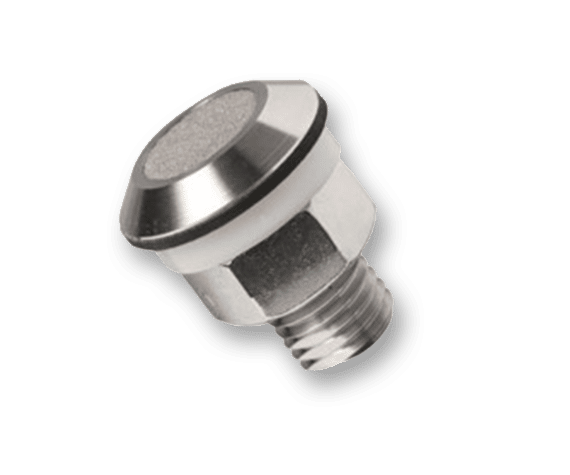

Fluidisation Pad & Ventilation Nozzle made out of Sinter

Function: Fluidisation via sintered metal elements directly into the product

Fluidisation Pad made of Silicone

Function: Fluidisation along the vessel wall with simultaneous vibration

RATEC Ventilation Nozzles for Bulk Materials

Optimization of Bulk Material Processes in Conveyor Systems

Ventilation nozzles made from silicone and sintered materials are specifically developed for the bulk materials industry to enhance the efficiency of material handling and transport. These nozzles ensure uniform air distribution within silos, conveyors, and containers, effectively preventing clumping, bridging, blockages, and dust formation in your system.

Product Features of RATEC Ventilation Nozzles

Our ventilation nozzles provide outstanding features, making them a reliable solution for bulk material applications:

- Wide Range of Materials

- Silicone: Flexible and resistant to extreme temperatures and chemical exposure. Ideal for use in harsh environments or at elevated temperatures where extended operational reach is required.

- Sintered Materials: Made from highly porous structures offering excellent air permeability and high mechanical strength. These nozzles are exceptionally durable, operate silently, and are well-suited for demanding chemical and pharmaceutical applications.

- Optimized Aeration: The nozzles provide even air distribution, enhancing the efficiency of aeration and bulk material fluidization. This helps prevent blockages and bridging in silos and containers.

- Durability and Resistance: Thanks to their abrasion and corrosion resistance, our nozzles offer a long service life and help reduce maintenance costs.

- Easy Installation: Modular design allows for seamless integration into various plant systems and containers. Both internal and external mounting options are available, minimizing downtime.

- Versatile Applications: The aeration nozzles are ATEX and FDA compliant and suitable for a wide range of industries including food, pharmaceuticals, chemicals, building materials, and recycling.

Application Areas of RATEC Ventilation Nozzles

RATEC ventilation nozzles provide tailored solutions for various bulk material applications:

- Bulk Storage: Prevent clumping of materials such as flour, sugar, grain, fertilizer, cement, or plastic granules in silos and storage tanks.

- Conveying Systems: Ensure consistent material flow and prevent blockages in conveyor lines, chutes, and piping.

- Packaging and Filling Processes: Promote uniform aeration and material distribution during filling of big bags, containers, or boxes.

- Chemical and Pharmaceutical Processing: Optimize airflow and reduce dust generation during handling of powders or granules in industrial processes.

Advantages of RATEC Ventilation Nozzles

Using ventilation nozzles offers numerous benefits:

- Improved Material Flow: Targeted aeration prevents bridging and blockages, ensuring smooth operation in silos and conveying systems.

- Energy Efficiency: Optimized air distribution reduces air consumption, resulting in energy savings.

- Enhanced Safety: By reducing dust accumulation and blockages, the risk of explosions or other dust-related hazards is minimized.

- Long Service Life and Low Maintenance: Durable materials ensure extended lifetime and simplify maintenance routines.

- Flexibility: Available in various sizes, colors, and configurations for integration into different systems.

Industries Served

Our ventilation nozzles are used across a wide range of industries:

- Food Industry (e.g. for flour and sugar storage)

- Pharmaceutical Industry (e.g. for handling powders and granulates)

- Chemical Industry (e.g. during processing of chemical substances)

- Building Materials Industry (e.g. cement handling)

- Recycling Industry (e.g. processing of recyclable materials)

RATEC ventilation nozzles offer an efficient solution for optimizing bulk material handling processes across various industries. With a wide selection of materials, easy installation, and reliable performance, they help ensure smooth system operation, energy savings, and safe, efficient production workflows.

Need Consultation? Contact us – we’ll be happy to advise you on the ideal material and nozzle configuration for your specific application requirements!