discover

Pigging

Systems

Fixed Pigging System Type: KFM

Fixed pigs are brush pigs with only a single main body. The bristle arrangement cannot be changed.

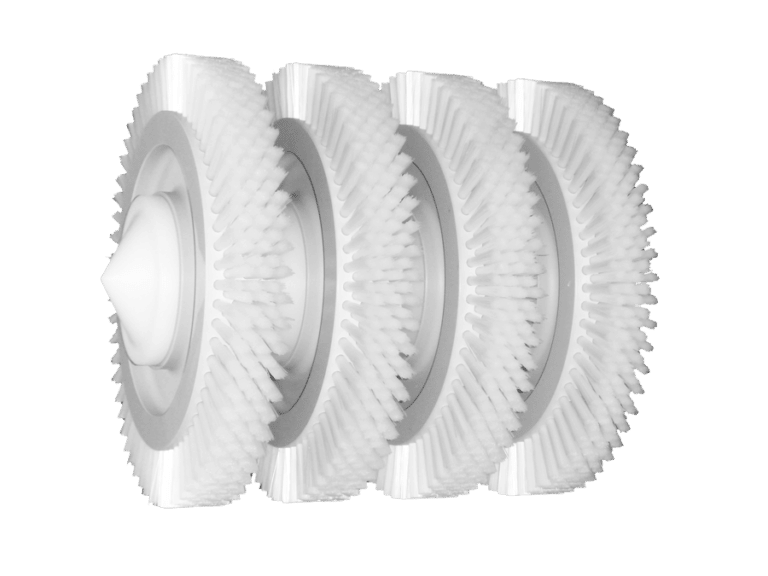

Modular Pigging System Type: KMM

Modular pigs are brush pigs with multiple main bodies. The user has the option to replace individual main bodies or exchange them for others.

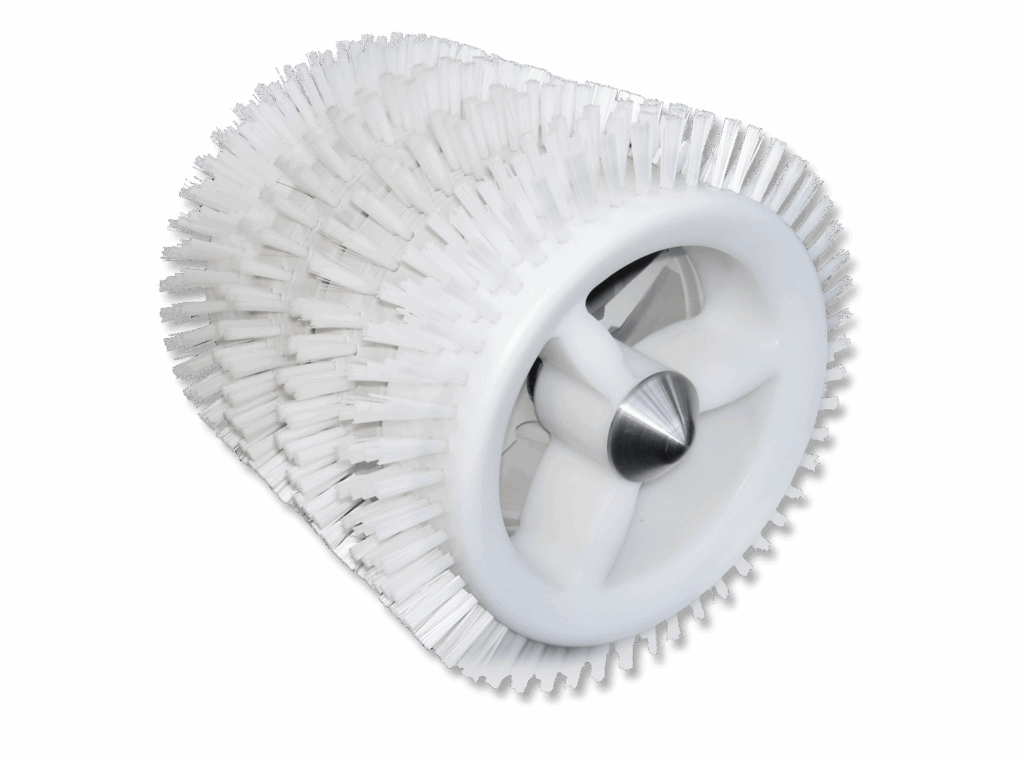

Turbo Pigging System Type: KTM

Turbo pigs are brush pigs where the brushes rotate in opposite directions during movement inside the pipe.

Special Pigging System

Pigging systems for special tasks, e.g. drying, polishing or cleaning of flexible tubes.

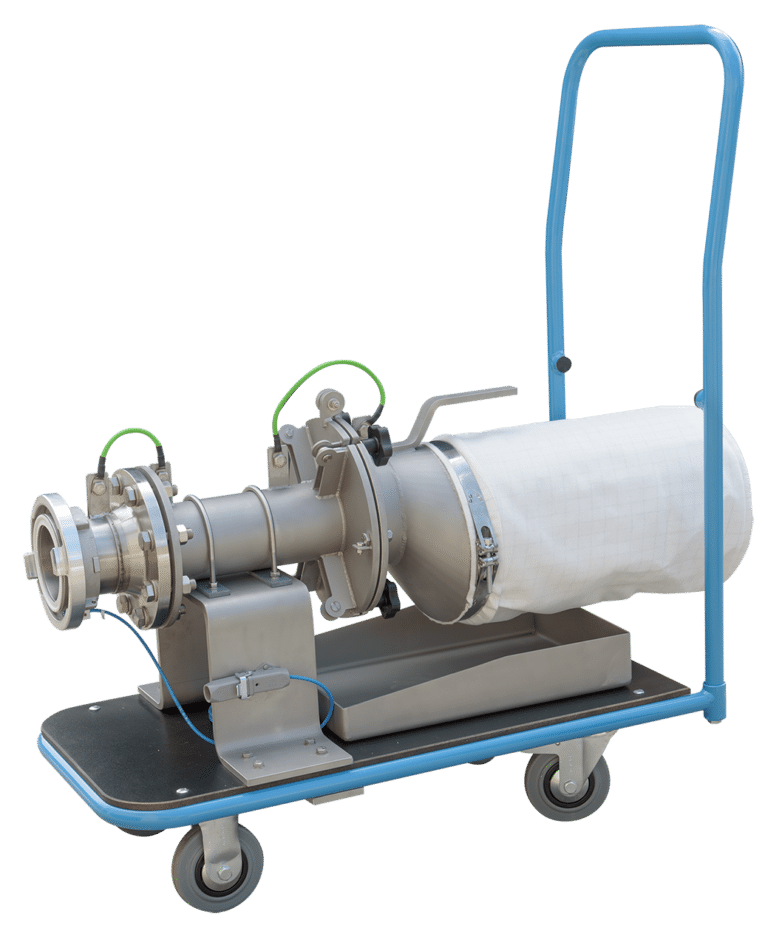

Transmitting and Receiving Stations

Components for inserting and removing pigs from the pipeline.

Pigging Systems for Pneumatic Conveying

Efficient Cleaning and Maintenance of Pipeline Systems

Pigs are specialized cleaning and maintenance tools that play a central role in pneumatic conveying. They ensure product quality and enable efficient bulk material transport by removing deposits, residues, and contaminants from pipelines. Our pigging systems significantly contribute to making pipeline operations safer and more cost-effective.

Applications of Pigging Systems

Pigs are used across almost all areas of pneumatic conveying in the bulk goods industry. They are especially important when:

- Consistently high product quality must be ensured,

- Pipeline clogging needs to be prevented,

- And contamination must be avoided during product changes.

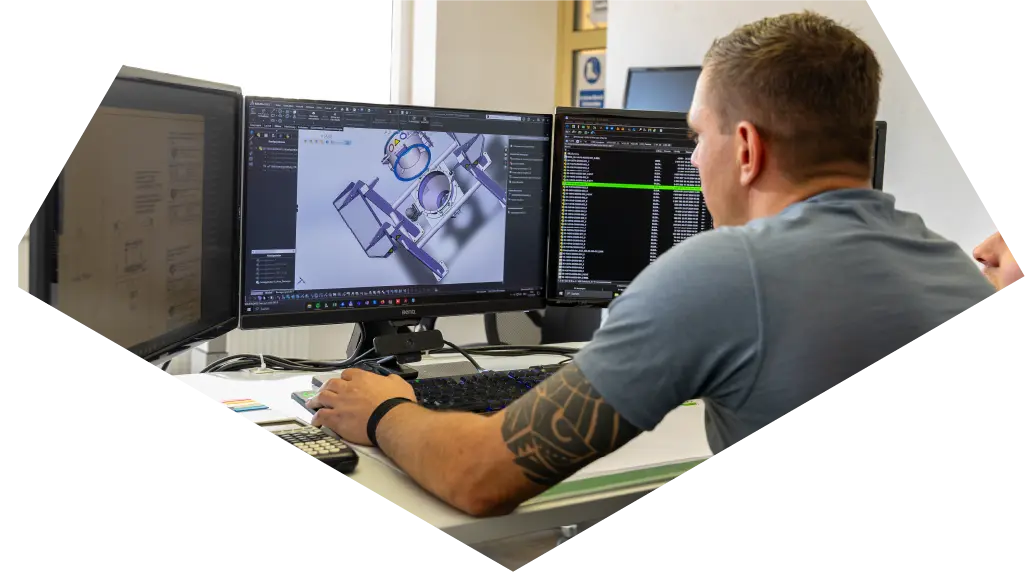

Why Choose RATEC Pigging Systems?

Our pigs offer numerous benefits that greatly reduce maintenance effort:

- Cost-effective cleaning of pipelines in pneumatic conveying systems.

- Prevention of blockages and deposits in pipelines.

- Increased hygiene and product quality through regular cleaning.

Which Conveying Pipelines Can Be Cleaned with Pigs?

- Both pressure and suction pipelines can be cleaned effectively with pigging systems.

Purpose and Benefits of Pigging

Pigging offers many advantages for pipeline systems:

- Removal of dust, lint, and other deposits from pipelines.

- Improvement of product quality and hygiene standards.

- Prevention of contamination and product carryover during product changes.

- Avoidance of pipeline blockages and buildup inside the lines.

Industries Using Pigging Systems

Pigging systems are indispensable in many industries:

- Plastics industry

- Building materials industry

- Food industry

Features and Variants of Our Pigs

Our pigs are available in various sizes, materials, and shapes to suit different applications. The pigging systems range from simple pig balls to complex turbo pigs, all tailored to the specific requirements of your pipeline systems.

Components of a Pigging System

A complete pigging system consists of several components:

- Pig launching station (manual, semi-automatic, or fully automatic)

- Propulsion gas unit (air supply for pneumatic conveying)

- Pig receiving station (manual, semi-automatic, or fully automatic with pig return)

- Disposal unit for contaminants (not always required)

- Control unit (optional)

Advantages of Pigging Systems

Using pigging systems provides numerous benefits:

- Reduced downtime and maintenance costs through efficient cleaning without pipe disassembly.

- Consistent conveying performance and operational conditions over the system’s lifetime.

- Increased safety by minimizing hazardous material residues in pipelines.

- Environmentally friendly, as pigging operates without chemicals or cleaning agents.

Types of Pigs

We offer a variety of pigs for different requirements:

- Pig balls

- Fixed pigs

- Modular pigs

- Turbo pigs

Special pig designs

For special requirements, we also provide:

- Pigs for ATEX zones (explosion-proof pigs)

- FDA-compliant pigs for the food industry

- Detectable pigs

Handling and Operation of Pigging Systems

Our pigging systems are easy to operate, allowing fast and efficient cleaning without lengthy downtime. Our sending and receiving stations guarantee effortless launching and retrieval of the pig.

When Is Pigging Not Possible?

There are certain conditions where pigging is not feasible:

- Pipelines with large diameter changes

- Internal pipeline fittings or obstacles

- Severe crusting inside the pipes

- Excessively large product volumes inside the pipe

For existing systems that are not piggable, we offer tailored solutions and modifications to adapt the system to your specific requirements.