discover

Sampling

Systems

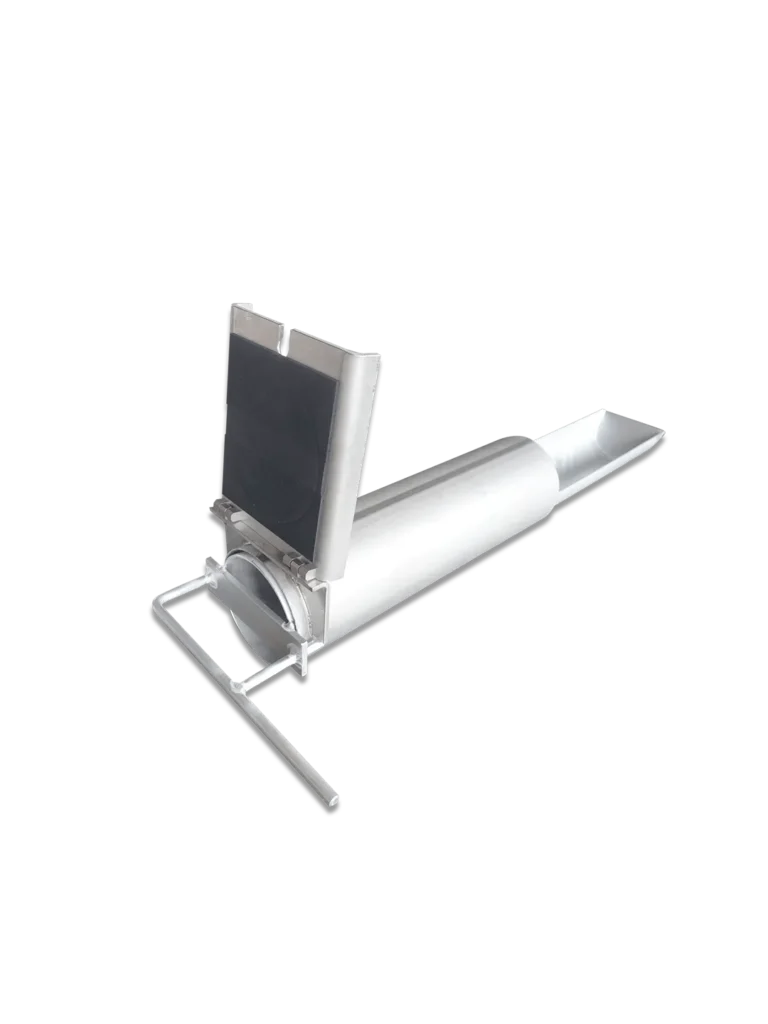

Belt Sampler

The belt sampler is used for taking samples from conveyor belts. A swivel arm is swung into the product flow, extracts a defined sample quantity, and transfers it into the sample container at the end position. After sampling, the swivel arm returns to its parked position outside the product flow. The drive is electric or pneumatic, depending on the process requirements.

Piston Sampler

The piston sampling unit enables targeted sampling of bulk materials from silos, containers, chutes, drop pipes, and conveyor lines. It can operate either intermittently—by extending and retracting the piston for single sample collection—or continuously, where the piston induces a steady product flow. The drive can be manual, electric, or pneumatic. The DN50 size reliably covers common applications. Optional features such as a weld-on end or position feedback expand the range of applications and facilitate integration into automated processes.

Rotary Piston Sampler

The rotary piston sampler enables the extraction of samples from silos, containers, chutes, drop pipes, and conveyor lines. A piston with rotary drive opens the sampling port, allowing sampling to be performed continuously or intermittently. The drive can be manual, electric, or pneumatic, depending on the specific process requirements. The DN100 size ensures reliable sampling even with larger product volumes.

Sample Collector / Sample Magazine

The sample collector enables automatic collection of individual samples in a carousel or linear magazine with up to 48 sample containers. Samples are filled directly into containers, bottles, or bags and can then be easily transported to the laboratory. The drive can be manual, electric, or pneumatic, allowing the system to be customized to specific process requirements.

Screw Sampler

The RATEC screw samplers enable controlled sampling of bulk materials from silos, containers, and drop pipes. The product is conveyed directly into a sample container via a screw conveyor—driven manually, electrically, or pneumatically. Available in sizes DN35, DN50, and DN80, they can be flexibly adapted to various requirements. Options such as different housing designs, drives, and sample containers make them a versatile solution for process-accompanying, representative sampling.

Special Samplers & Sample Transport Systems

Special samplers provide a tailored solution for sampling from nearly all types of bulk materials. They can be individually adapted to the specific requirements of the material. Sample transport systems, such as pneumatic tube systems or systems with pneumatic conveying, ensure safe and efficient transport of samples from the sampling point to the laboratory or analysis area

Swivel Sampler

The swivel sampler enables precise sampling of product from drop pipes. A swivel arm moves into the product flow, takes a defined sample quantity, and diverts it outward. After sampling, the swivel arm returns to its parked position outside the product flow. The drive can be manual, electric, or pneumatic, allowing flexible adaptation to the specific process requirements

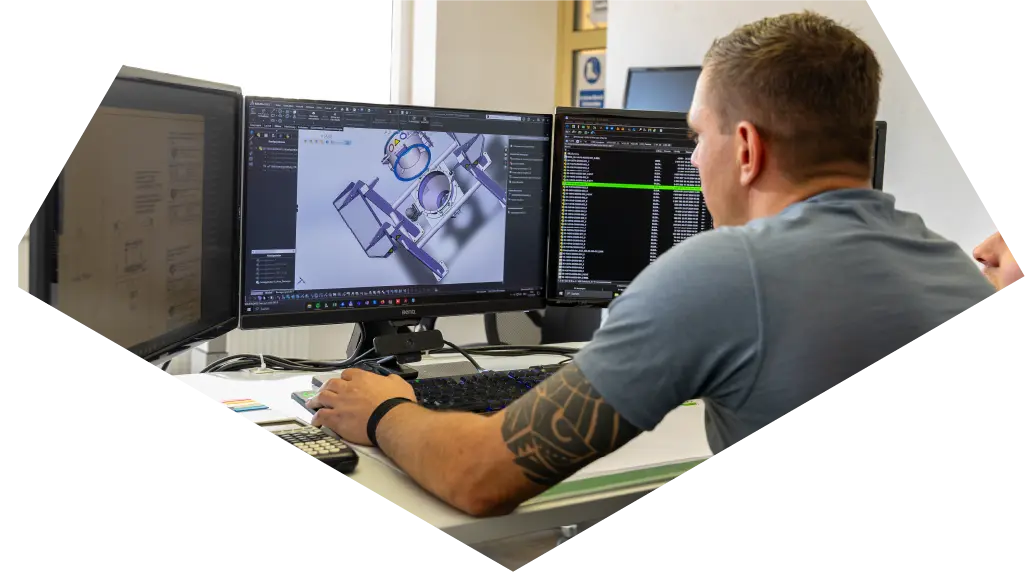

RATEC Sampling Systems

Precise Sampling Systems for Bulk Materials

RATEC samplers provide a precise, reliable, and efficient solution for taking samples from a wide variety of bulk materials such as powders, granulates, dust, and other substances. Our sampling systems are specifically designed to meet the requirements of the bulk material industry and manufacturing processes, ensuring accurate sampling for quality control, process monitoring, and research. With our samplers, you always obtain a representative sample that delivers valuable information about the quality of your raw materials or finished products.

Features of RATEC Sampling Systems

RATEC samplers offer numerous advantages that make them a reliable choice for your sampling processes:

Accurate Sampling: Our samplers guarantee uniform and representative sample extraction across the entire bulk material volume, ensuring correct results and minimizing bias in analysis.

Automated and Manual Models: We offer manual samplers, ideal for small quantities or spot sampling, as well as pneumatic and electric sampling systems for automated processes, so you can find the perfect system for your specific needs.

Versatile Application: Suitable for a wide range of bulk materials including powders, granulates, grains, and other materials in various sizes and densities. Can be used in silos, conveyor systems, production lines, or mixing plants.

Robust and Durable: Made from high-quality, corrosion-resistant materials that reliably operate under harsh conditions. Designed for long service life with minimal maintenance.

Easy to Use: Our sampling systems are user-friendly and require no extensive training. Both pneumatic, electric, and manual models enable quick and simple sampling that integrates seamlessly into existing production processes.

Hygienic and Safe: Easy to clean and compliant with applicable hygiene standards, helping to avoid contamination and ensuring safe handling even with hazardous or harmful materials.

Applications of RATEC Sampling Systems

RATEC samplers are used in various industries and processes:

Quality Control: Regular sampling for analyzing material properties such as particle size, moisture content, chemical composition, or homogeneity ensures your products meet the desired quality standards.

Research and Development: Sampling for laboratory tests, material comparisons, or optimization processes in product development. Precise sampling systems help achieve accurate results.

Process Monitoring: Samplers enable monitoring of production lines to ensure process parameters remain consistent, thereby maintaining product quality.

Storage and Silo Management: Ideal for sampling from silos, storage containers, or during transport of bulk materials to ensure consistent quality.

Advantages of RATEC Sampling Systems

RATEC samplers offer numerous advantages for your bulk material processes:

High accuracy in sampling for precise and reliable material analysis.

Efficient and Time-Saving: Our systems enable fast and error-free sample collection, optimizing the entire process.

Adaptable to your Requirements: Flexible for different bulk materials and applications.

Reliable material analyses improve product quality and process optimization.

Robust Construction: Durable and easy to maintain, protecting your investment.

Simple Operation: Both manual and automated models are easy to handle.

Hygienic and Safe: Ideal for use in sensitive environments, compliant with hygiene standards.

FDA and ATEX compliant: Suitable for use in regulated and safe environments.

RATEC Sampling Systems – The Perfect Solution for Precise Sampling

With RATEC samplers, you receive a reliable, precise sampling system for your bulk materials. Optimize your process monitoring, quality control, and research & development with a sampler that guarantees high accuracy, durability, and user-friendly operation.

Trust RATEC for the best solution in bulk material sampling and enhance the quality and efficiency of your production processes!